type of impact test|instron impact tester : bespoke The impact test usually evaluates the brittleness, toughness, notch sensitivity, and impact strength of materials to resist high rate loading. The ability of a material to pass the impact .

WEBEmagrecentro Cabo Santo Agostinho. Emagrecer de forma rápida em pernanbuco Conheça nosso método exclusivo para emagecer e pernanbuco.

{plog:ftitle_list}

WEB1º - Selecione um tipo de rifa dentre os disponíveis (Grupo, Dezena, Centena ou Milhar) a data de sorteio e a loteria. 2º - Monte seu palpite selecionando manualmente ou use a geração automática escolhendo quantas cotas desejar. Você pode escolher mais de um palpite por rifa. 3º - Clique em Incluir Aposta, confira tudo no carrinho de .

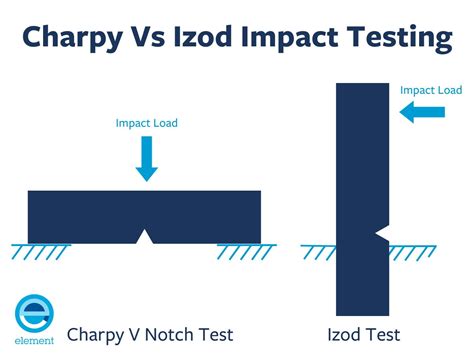

Real-world impact simulation helps identify potential weaknesses, optimize material formulations, and improve product designs. The main types of impact testing, including Charpy, Izod, drop weight, and puncture impact testing, employ distinct technologies and .Types of Plastics Impact Testers. The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused . Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to guarantee .There are two traditional standards for measuring impact resistance: the Charpy pendulum impact test (ISO 179/ASTM D6110) and the Izod test (ISO 180/ASTM D256). These two test methods are used to certify the impact resistance of a .

There are two main forms of impact test, the Izod and the Charpy test. Both involve striking a standard specimen with a controlled weight pendulum travelling at a set speed. The amount of energy absorbed in fracturing the test piece is .

The impact test usually evaluates the brittleness, toughness, notch sensitivity, and impact strength of materials to resist high rate loading. The ability of a material to pass the impact .The impact test is to study the safety and reliability of WAAM component when subjecting to external impact forces, and the measured impact absorption work determines the toughness .An impact test is a simple technique that can be used to excite resonances of flexible substructures. A significant advantage of the method is that mechanical natural frequencies .

Impact testing serves to assess a material’s impact toughness, representing its resistance to impact forces. The ability to quantify the impact property is a great advantage in product liability and safety. This involves .

Impact testing is testing an object's ability to resist high-rate loading. An impact test is a test for determining the energy absorbed in fracturing a test piece at high velocity. Most of us think of it as one object striking another object at a .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see Fig. 6.9), which gives an indication of the toughness of a material at a specified temperature.It is not a particularly accurate test but can give a general indication of the ability .Generally, the impact testing methods can be divided into two separate types: low velocity impact by a large mass (drop-weight tests or pendulum) and high velocity impact by a small mass (runway debris or small arms fire) [25]. The more common methods are low velocity impact by a large mass.

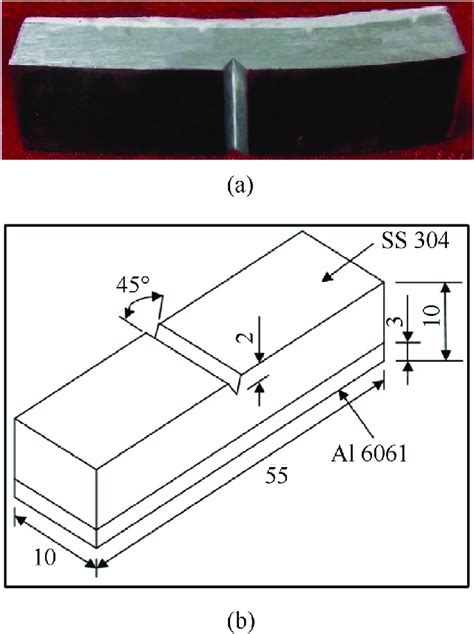

Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of impact testing subsize specimens down to ¼ size. IZOD Impact Testing can be done up to 240 foot-pounds. on standard single notch and type-X3 specimens.What is an impact testing machine? An impact testing machine is used to determine the resistance of a material or component to a rapid load under varying temperature conditions. Depending on the material to be tested, the end-use application requirements, and the preferred type of test data, a choice is made between pendulum impact testers and .Study with Quizlet and memorize flashcards containing terms like What are the unique qualities of AR 385-63/MCO 3570.1D?, The minimum distance that targets are engaged firing a MK-19 grenade launcher with HE ammunition is, In the context of DRM and range safety, mitigation of risk is the ability to and more.Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy . Other types of impact tests, including Tensile Impact, Dynstat, and Pipes can be carried out using a pendulum1.

izod impact test vs charpy

instron impact tester

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

The most popular impact tests are the Charpy test and the Izod test. These two tests determine essentially the same material characteristics, but differ in the orientation of the test sample, which causes the sample to be stressed in different directions and involves a known weight released from a known height colliding with the sample in its test structure.

Impact testing is a type of mechanical testing that is used to determine how a material responds when subjected to high strain-rate loading. It is a useful tool for evaluating the mechanical properties of materials, especially their ductile-brittle transition properties. The test is performed using instrumented equipment capable of measuring .

Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch . Specimen Position. Horizontally, Notch facing away from the pendulum. Vertically, Notch .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Charpy Impact Test: In this method, a test specimen is held at one end and struck on the opposite end with a pendulum hammer. The amount of energy absorbed by the specimen during fracture is measured. Izod Impact Test: . When to perform a statistical test. You can perform statistical tests on data that have been collected in a statistically valid manner – either through an experiment, or through observations made using probability sampling methods.. For a statistical test to be valid, your sample size needs to be large enough to approximate the true distribution of the population .

ImPACT, which stands for Immediate Post-Concussion Assessment and Cognitive Test, is a common testing protocol in the area of brain injury. Developed in the late 1990s at the University of Pittsburgh and released in the early 2000s, the test is the only FDA-approved tool for concussion assessment.The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a . The Two Types of Charpy Impact Test Results 1. Quantitative Results. Quantitative data is data based on numerical values. In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. The DBTT (Ductile-to-Brittle Transition Temperature) can also be estimated by testing the multiple samples .

of a material. It can classify the different types of materials into either brittle or ductile materials. Two basic types of impact testing 1) Charpy impact test The specimen is supported as a simple beam with the load applied at the center. The position of latching tube is set to 140° The specimen is supported horizontally from two sides 2 . In conclusion, impact testing is a crucial type of material testing used to evaluate the ability of materials to withstand sudden and forceful loading. The methods of impact testing include Charpy, Izod, and drop weight testing, and the results are expressed in joules or foot pounds. Impact testing is widely used in various industries to ensure .Example: Non Functional Testing. Functional testing types include unit testing, integration testing, and more. It ensures that the app functions as it should. On the other hand, there's non functional testing. Non functional testing is a type of testing that focuses on how well the app works. While functional testing focuses on IF the app works .

Impact testing is a type of material testing. It can measure the material’s ability to resist fractures and damages when subjected to a sudden impact. Materials are frequently used in construction, manufacturing, and other industries. It is an essential method for testing the suitability of these materials.

impact test specimen size

impact test for plastic material

08/10/2023. Vídeo mostra homem sendo punido por dever di.

type of impact test|instron impact tester